This is the air intake of the mechanical fuel injector. This is not just a "scoop", or air-scoop; the red butterfly plates that swing open are actually precision parts that meter the air very exactly(this part is called the "hat"). Believe it or not they flow enough air like this, nearly completely closed, for my big block motor to run at idle. You can barely see a little opening at the bottom of the center butterfly plate.

This is the air intake of the mechanical fuel injector. This is not just a "scoop", or air-scoop; the red butterfly plates that swing open are actually precision parts that meter the air very exactly(this part is called the "hat"). Believe it or not they flow enough air like this, nearly completely closed, for my big block motor to run at idle. You can barely see a little opening at the bottom of the center butterfly plate. Anyway, the injector system has some drawbacks, and I have never been completely satisfied with it. For one thing, it only works in two modes, idle, and wide open (and not really well at idle). Part throttle is difficult, so it's hard to drive the car around the pits and to the starting line, and so forth. While the system looks complicated, it's actually pretty simple, but maybe that's just to me since I understand how it works. The other thing is it uses methanol alcohol instead of gasoline. The alcohol makes huge power and keeps the motor temperatures very cool (the cooling effect is the main reason I run alcohol), but you have to drain the entire system at the end of every day or it will corrode the internals.

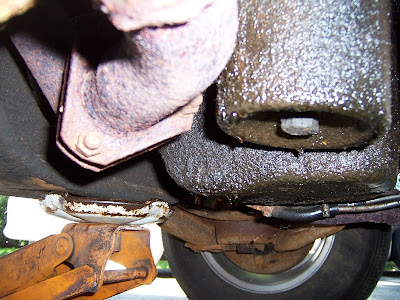

Anyway, the injector system has some drawbacks, and I have never been completely satisfied with it. For one thing, it only works in two modes, idle, and wide open (and not really well at idle). Part throttle is difficult, so it's hard to drive the car around the pits and to the starting line, and so forth. While the system looks complicated, it's actually pretty simple, but maybe that's just to me since I understand how it works. The other thing is it uses methanol alcohol instead of gasoline. The alcohol makes huge power and keeps the motor temperatures very cool (the cooling effect is the main reason I run alcohol), but you have to drain the entire system at the end of every day or it will corrode the internals. I took a couple of shots to show how the lines and components run, just for some sort of unknown reference, I guess.

I took a couple of shots to show how the lines and components run, just for some sort of unknown reference, I guess.-

I took the whole injector system off the motor. That left the bare block in the car, so I put my old faithful gas carburetor and intake manifold back on there, just for kicks.

It's missing a couple of hoses, but you can see how much simpler the carburetor is. Again, just for kicks, I hooked the throttle cable up, it went right on after I made one simple bracket. The exhaust is removed in this photo, I have rags in the ports to keep moisture out. The carb set-up is not as trick looking as the injector for sure though.

It's missing a couple of hoses, but you can see how much simpler the carburetor is. Again, just for kicks, I hooked the throttle cable up, it went right on after I made one simple bracket. The exhaust is removed in this photo, I have rags in the ports to keep moisture out. The carb set-up is not as trick looking as the injector for sure though.-

This got me thinking. I have made no progress on the Biscayne since I am in voluntary austerity mode right now (basically put: I don't want to spend any money on it since I'm not working). So that's not running yet. I want to sell the altered so I'd have some money to spend on the Biscayne, but I don't want to sell it into a recession and lose a lot of money on it. That would just be foolish for no reason. The time to sell race cars is when the economy is humming along. Finally, for the cost of a couple of small parts, I could always race this thing again with the carb set-up. I have let my competition license and the car's chassis certification lapse, but they are only needed to run sub-10 seconds. I could easily adjust the throttle stop, and slow it down to run low 10's in the slower class. So we'll see. Besides, little k says she wants to see the purple car go "vrooom".

-

I am getting very antsy to get back to work. Not because I'm excited about working, but my life is on hold right now, I feel like I can't do anything, or spend any money until I have some coming in. Most car events are closing up for the season, so I'm having a hard time coming up with things to write about. This may be a long, cold winter.